Respect for Human Rights

Respect for Human Rights

We will strive to minimize human rights risks throughout our global supply chain and earn the trust of our stakeholders.

Contributable SDGs and Targets

Respect for human rights forms the foundation of the ITO EN Group’s management principle, “Always Putting the Customer First,” and underlies all of our business activities. In accordance with the United Nations Guiding Principles on Business and Human Rights, the ITO EN Group has established policies, including the Human Rights Policy and Fundamental Supplier Policy, to encourage respect for human rights and achieve sustainable supply chain management.

Policy

Human Rights Policy

The ITO EN Group has formulated the ITO EN Group Human Rights Policy based on advice from external experts with specialized knowledge and practical experience in matters regarding human rights. The policy was approved by ITO EN's Board of Directors before being signed by the president.

To share this policy, it is translated into the languages spoken in the countries and regions where the ITO EN Group operates. All of our officers and employees are continuously provided with the education and training necessary for implementing the policy. We share the policy with our suppliers so they can understand and support it. Furthermore, we check and assess how they comply with the policy and collaboratively promote initiatives to respect human rights in the supply chain.

Process for formulating the policy

When we were formulating the ITO EN Group Human Rights Policy based on the United Nations Guiding Principles on Business and Human Rights in March 2020, we engaged in dialogue with stakeholders including human rights experts.

System (governance)

About the promotion structure

The ITO EN Group considers respect of human rights as an important issue and its Chief Human Resource Officer (CHRO) who is responsible for personnel and human rights issues oversees the establishment of a framework for promoting initiatives led by the Risk Management Committee (chairperson: president), an advisory body to the Board of Directors. The Risk Management Committee discusses plans and initiatives regarding human rights due diligence and reports information about them to the Board of Directors.

The committee also cooperates with the Sustainability Promotion Committee (chairperson: president).

* Reports and agenda items regarding human rights issues submitted to the Board of Directors and the Risk Management Committee

| Date | Meeting body | Report/agenda item |

|---|---|---|

| September 2023 | Risk Management Committee | ITO EN Group's initiatives to mitigate human rights risks |

| March 2024 | Risk Management Committee |

|

| April 2024 | Board of Directors | Board of Directors Report on Human Rights Due Diligence in the first half of FY4/2024 |

| September 2024 | Risk Management Committee | Human rights due diligence initiatives in the first half of FY4/2025 |

Human rights due diligence

The ITO EN Group engages in dialogue with its stakeholders based on the ITO EN Group Human Rights Policy and, with the cooperation of human rights specialists, structures and implements its human rights due diligence framework for working to identify, evaluate, prevent, mitigate, monitor and redress human rights risks. The progress of our initiatives regarding respect for human rights is made available on our website, in integrated reports and in other media.

Implementation process

Progress to date

As we began implementing human rights due diligence activities in 2023, initiatives are under way with the help of Caux Round Table (CRT) Japan.

| Months and years | The ITO EN Group's initiatives |

|---|---|

| March 2023 | A training session is held for the management personnel of ITO EN Group companies. |

| April 2023 | A study session on business and human rights and a workshop on human rights due diligence risk assessment are held for managerial-level employees in major departments. |

| June 2023 |

Human rights impact assessed Non-Japanese workers of agricultural corporations Non-Japanese workers of our in-house factories |

| October 2023 | CHRO presented ITO EN's initiatives regarding human rights due diligence at the 2023 Business and Human Rights Conference (the12th) sponsored by CRT Japan. |

| May 2024 | Established the ITO EN Group Supplier Hotline |

| September 2024 |

Conducted follow-up evaluations (monitoring) Human rights impact assessed |

Assess human rights risks

Process for identifying human rights risks

In 2023, we defined important human rights themes based on the results of a survey conducted in accordance with the following process in cooperation with CRT Japan.

1. Secondary research to assessment human rights risks (April)

Human rights risks in the countries where we conduct business were assessed using CRT Japan’s knowledge.

2. Identification of human rights themes at the human rights due diligence risk assessment workshop (April)

A workshop was held with managerial-level people from major departments to discuss global trends related to business and human rights and changes in the things that society demands from companies, before identifying latent human rights issues in our supply chains and the rights holders that are negatively impacted (workers, communities, ITO EN’s employees and consumers in the supply chain).

3. Interviews with related departments (May)

CRT Japan conducted research and analysis to dig deeper into the identified human rights themes.

High priority human rights themes

Work environment of tea producers and non-Japanese workers at our in-house factories

Working environment for workers at contractors (production, logistics, waste)

Work environment for workers and impact on the environment for nearby residents at overseas raw material suppliers (Central and South America)

Human rights impact assessments and follow-up evaluations

A human rights due diligence workshop on the assessment of risk was held in April 2023 and the human rights themes we should address were specified. Based on these themes, we conducted human rights impact assessments (HRIA) and follow-up evaluations (monitoring) in our green tea business, the area where our Company has the greatest procurement capabilities.

*)ASSC(The Global Alliance for Sustainable Supply Chain)| Human rights theme | Human rights impact assessment | Follow-up evaluations (monitoring) |

|---|---|---|

| Work environment of tea producers and non-Japanese workers at our in-house factories | Foreign workers at two agricultural corporations involved in the new tea plantations business and at the Shizuoka Plant Report on the assessment of human rights impact regarding non-Japanese workers (FY4/2024) | Foreign workers at two agricultural corporations involved in the new tea plantations business Follow-up evaluation report (FY4/2025) (Japanese Only) |

| Foreign workers employed by secondary and tertiary suppliers engaged in contract farming Human rights impact assessment report (FY4/2025)(Japanese Only) |

Remedy

In accordance with the United Nations' Guiding Principles on Business and Human Rights, the ITO EN Group will provide individuals with access to effective remedies and will provide fair and equal grievance mechanisms. If we identify that we have caused or contributed to adverse impacts on human rights, we will take appropriate remedies and corrective measures.

ITO EN Group employees, consumers and members of local communities

The ITO EN Group has set up the ITO EN Group Corporate Ethics Hotline. As a contact point for whistleblowing, it is open to anyone including customers. In addition, the ITO EN Group Global Hotline has been in place since 2023 as a whistleblowing contact point exclusively for ITO EN Group companies based outside Japan. Both hotlines accept reports, consultations and questions.

Employees of suppliers for ITO EN Group

The ITO EN Group has been operating the ITO EN Group Supplier Hotline since May 2024. From employees of suppliers as significant partners of the ITO EN Group, it accepts consultations on employment and the working environment and on other matters regarding compliance and consultations concerning transactions with the ITO EN Group.

[Service Hours]

The hotline is open to receive contacts 24 hours a day everyday.We will respond within business hours.

Business hours (JST): 9: 00~17: 00 (except holidays on Saturdays, Sundays, Japan, Japan holidays and year-end and New Year holidays)

[Service Languages]

Japanese and English Available (as of May 2024)

Eligible users

The hotline is open to anyone engaged directly or indirectly in any of the processes related to ITO EN Group products, such as crude tea procurement, processing, production, logistics, sales and distribution. (ITO EN Group employees, consumers and members of local communities are asked to contact the ITO EN Group Corporate Ethics Hotline.)

Subjects accepted for consultation

The Hotline accepts consultation on any conduct that deviates from the ITO EN Group Human Rights Policy, the ITO EN Group Procurement Policy, the ITO EN Group Fundamental Supplier Policy and the Supplier Code of Conduct based on the ITO EN Group Fundamental Supplier Policy and on any matter related to these Policies and the Supplier Code of Conduct. Specific examples include product safety issues, problems about commercial transactions and matters concerning the working environment including human rights and labor issues.

- ITO EN Group Human Rights Policy

- ITO EN Group Procurement Policy

- ITO EN Group Fundamental Supplier Policy

- Supplier Code of Conduct based on the ITO EN Group Fundamental Supplier Policy

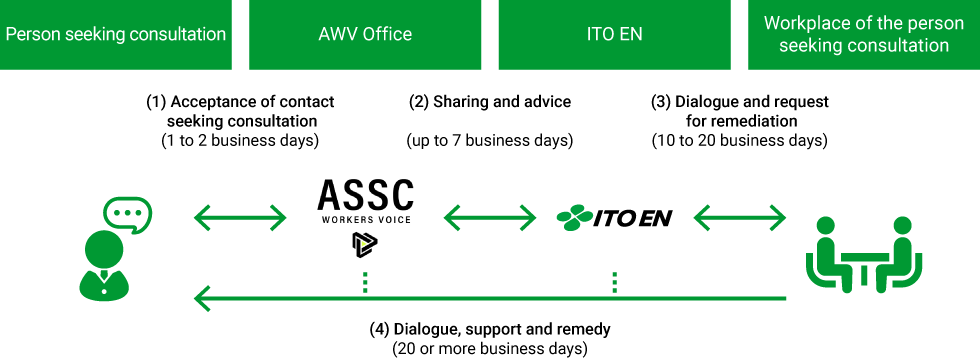

Hotline process flow

(1) A person seeking consultation uses the contact form at the AWV Office (*), which is a third-party organization.

(2) The consultation details is shared with ITO EN. After confirmation from workers, we will verify the facts.

We may visits the workplace, conduct dialogues or request remediation which are consultations, giving corrective action plans and monitoring.

(3) Basically, the organization to which the person seeking consultation takes the initiative in solving the issue. Depending on consultation subjects, ITO EN, the AWV Office or a public institution may possibly play a central role in protecting the person seeking consultation.

-

* The AWV Office is operated by the Global Alliance for Sustainable Supply Chain (ASSC), which is an organization specializing in human rights and labor issues that works with companies to solve problems on supply chains.

Non-disclosure obligations and protection of persons seeking consultation and whistleblowers

Protection of persons seeking consultation is given priority. They will never be subject to disadvantageous treatment because of the consultation.

The ASSC and ITO EN have concluded a non-disclosure agreement.

The ITO EN Group manages personal information in accordance with the matters subject to disclosure under the Privacy Policy.

It is possible to seek consultation anonymously. In this case, investigations into the facts may necessarily be limited.

While giving consideration to protecting the anonymity of the person seeking consultation, the incident may be disclosed on the ITO EN website.

Implementation of activities to raise awareness of human rights and human rights training

Human rights awareness-raising activities for management and employees

The ITO EN Group provides the education and training necessary for implementing the ITO EN Group Human Rights Policy.

In 2023, we held training sessions for management and executives at ITO EN Group companies. Business and human rights experts were invited to lecture. As part of compliance education, training sessions for employees also discuss topics such as power harassment and sexual harassment.

Meanwhile, by addressing human rights issues through our business activities, we have sought to make employees more aware and understanding of human rights issues in local communities.

Human rights awareness-raising activities for suppliers

ITO EN communicates the ITO EN Group Human Rights Policy and the ITO EN Group Procurement Policy to suppliers during various quality meetings, supplier briefings. In line with the ITO EN Group Fundamental Supplier Policy and the Supplier Code of Conduct derived from it, we share our approach to human rights issues, etc. and work closely with suppliers to advance these initiatives.

Throughout the value chain of our existing businesses, we regularly conduct risk assessments that cover human rights, legal compliance, fair procurement, labor standards, and other key areas. When establishing relationships with new suppliers, we explain our policies, evaluation criteria, etc. and assess risks related to human rights, compliance, and occupational health and safety. When necessary, we also conduct on-site assessments to confirm actual operational conditions. Through ongoing communication with contract manufacturers, raw materials suppliers, material manufacturers, etc., including the sharing of information, exchanging of opinions, and confirmation of our future direction, we work to ensure that our related policies are clearly understood and entrenched throughout our supply chain.

Engagement in dialogue with stakeholders and experts

The ITO EN Group engaged in dialogue with suppliers, human rights specialists, outside organizations and other stakeholders and promotes initiatives for respecting human rights.

Stakeholder engagement

Caux Round Table (CRT) Japan

Since September 2023, meetings have been held to review our initiatives for respecting human rights in line with the United Nation Guiding Principles on Business and Human Rights.

ITO EN's human rights due diligence initiatives were announced by CHRO at the 2023 Business and Human Rights Conference (the 12th) held in October 2023.

From June to September 2024, we participated in the 2024 Japan Stakeholder Engagement Program hosted by CRT Japan. We engaged in a dialogue with NGOs, NPOs, experts, and other stakeholders on a wide range of social issues, particularly issues related to human rights and the environment, to which attention is paid in Japan and overseas, and we worked to identify key human rights issues in each industry.

The Consumer Goods Forum

In May 2019, ITO EN joined the Consumer Goods Forum's social sustainability working group to share information for the promotion of human rights due diligence and collaboratively eliminate forced labor.

The Global Alliance for Sustainable Supply Chain (ASSC)

Since May 2024, we have been working with the Global Alliance for Sustainable Supply Chain (ASSC) on the operation of the ITO EN Group Supplier Hotline and on consultations related to human rights issues in our supply chain.