Health of the Planet

Health of the Planet

We will work to solve environmental issues such as decarbonization and resource recycling through our business activities and create shared value with diverse stakeholders.

Themes and Key Performance Indicators (KPIs)

ITO EN Group Medium- to Long-Term Environmental Goals

Based on its management principle of “Always Putting the Customer First”, the ITO EN Group believes that it is its corporate social responsibility to protect the global environment shared by all of humanity, and pass it on to the next generation. Global environmental problems such as the increase in intensely hot weather, floods and landslides as a result of climate change due to global warming, and the problem of marine plastic garbage are now pressing issues for global society.

These kinds of issues are also key issues in the ITO EN Group's business activities. In September 2020, we formulated the ITO EN Group Medium- to Long-Term Environmental Goals with regard to our containers and packaging, and our response to climate change, based on the ITO EN Group Environmental Policy. Through these goals, we are further driving our initiatives to tackle environmental problems, with the aim of contributing to the creation of a sustainable society.

Medium- to Long-Term Environmental Goals

- CO2 emissions reduction targets

-

FY 2030 FY 2050 Scope 1&2 50% reduction in total emissions

(compared to FY2018)Net zero Scope 3 30% reduction in total emissions

(compared to FY2018)

- Water Resources

-

Reduce water used for manufacturing

Water consumption per unit of production: 3.0 m3/kl or less by FY2030

- Basic unit: water consumption per kl of production

- Dedicated in-house production lines at our own and partner factories

Implementation of water source conservation activities at Beverage Manufacturing Factory

We will promote water source conservation activities in collaboration with contractors and local communities in the watersheds that serve as water sources for our domestic group's beverage factories and Ito En's major beverage manufacturing contractors, with the aim of returning the water used in production activities to the water sources.

Water source recharge rate relative to water intake at each plant: 100% or more by FY2030Programs that give the public knowledge about the importance of water resources.

Monitoring and reducing water risks

companies associated with our entire supply chain, including suppliers of raw materials, to determine if they are high water stress watersheds or in regions susceptible to flooding. Appropriate measures are used to reduce vulnerability to these risk factors.

- Containers and packaging

-

3Rs (Recycle, Reduce, Replace & Reuse) + Clean (environmental conservation)

Aim to increase the ratio of recycled materials, including bio-derived materials, used as materials for producing PET bottles to 100% by 2030

Response to climate change

The ITO EN Group recognizes that the urgent global issue of climate change driven by global warming may also have serious repercussions for its business, including poor crop growth, disruptions to procurement, and suspension of operations due to weather-related disasters. We will focus on tackling climate change and strive to prevent global warming.

Response to the TCFD Recommendations

The ITO EN Group began conducting scenario analysis for green tea, which is its main raw material, in FY2020, to analyze the impact of climate change risks and opportunities on its business activities. In FY2021, we extended the scope of our analysis to include the entire value chain of ITO EN's business, analyzed risks and opportunities using 1.5°C/2°C and 4°C scenarios, assessed impacts on ITO EN's business, and considered countermeasures.

We also declared our support for the Task Force on Climate-related Financial Disclosures (TCFD)* recommendations in April 2022, to help solve issues related to climate change. We will actively promote the disclosure of information on the identification of climate change risks and opportunities and action taken to address them and will work to realize a sustainable society.

Aiming to reduce GHG emissions

In October 2020, the Japanese government declared that the country would achieve net zero greenhouse gas emissions, carbon neutrality, by 2050 and actions are under way accordingly. In support of the Japanese government’s decarbonization policy, the ITO EN Group has established a medium- to long-term environmental goal of achieving net-zero greenhouse gas emissions by FY2050. We are working to reduce greenhouse gas emissions throughout the Group to help realize this goal.

In compliance with the climate change-related laws established by the Japanese government, specifically the Act on Promotion of Global Warming Countermeasures and the Energy Conservation Act, we report our GHG emissions and energy consumption to the government once a year.

Industry initiatives

The Japan Soft Drink Association (JSDA) of which ITO EN is a member has participated in the Keidanren Voluntary Action Plan (VAP) on the Environment since its introduction in 1997. The soft drink industry is working to achieve carbon neutral.

In addition, ITO EN puts forward opinions on environmental regulations and regulatory standards and policy recommendations through the JSDA. We also verify in advance that our initiatives are in alignment with the JSDA's recommendations and views.

Participation in the Japan Climate Initiative*

In February 2019, ITO EN joined Japan Climate Initiative (JCI)* in support of its declaration: Joining the front line of the global push for decarbonization from Japan. Going forward, we will continue working with JCI and its member companies and organizations to actively tackle climate change, for the realization of a decarbonized society.

Overview of Japan Climate Initiative

| Name | Japan Climate Initiative |

|---|---|

| Founded | July 6, 2018 |

| Members | Companies, financial institutions, local governments, research institutes, NGOs and their coalitions which agree with the Founding Declaration |

| Leading advocate | Takejiro Sueyoshi, Special Advisor to United Nations Environment Programme Finance Initiative |

| Secretariat organizations | CDP Japan, WWF Japan, Renewable Energy Institute |

Promotion of energy efficiency

To promote the sustainable use of energy, ITO EN manages energy usage using the PDCA cycle approach incorporated in ISO14001 and all business units work to limit their usage.

Factories and offices

We are striving for efficient energy use at our factories (in production operations), introducing natural gas boilers and an LNG satellite station at our Okinawa Factory. We are also expanding our use of renewable energy, including by installing solar panels at factories operated by ITO EN and other Group companies. In our offices, including the offices of the sales, administrative, and research divisions, we thoroughly promote energy-saving initiatives such as our switch to LED lighting equipment at our head office building and our installation of high-efficiency air-conditioning systems at our bases. In addition, by transitioning to renewable-energy electricity plans and procuring environmental value certificates, we are accelerating Group wide efforts to increase our use of renewable energy.

Energy-efficient vending machines

We are seeking to reduce energy consumption by actively introducing more energy-efficient vending machines.

Eco-driving and introduction of eco-friendly vehicles

ITO EN is actively introducing eco-friendly vehicles, reducing fuel usage by planning more efficient sales routes, and promoting eco-driving at all its bases. As a result of these initiatives, fuel usage per vehicle has been falling continuously. We are also working to prevent air pollution by actively phasing in low-emission vehicles which meet the emission standards set by the government.

Water resources

The ITO EN Group is committed to reducing its own water intake and that of production lines used exclusively for ITO EN products at partner factories through measures such as promoting the use of recycled water in the beverage manufacturing process. We are also focusing on water source conservation activities in collaboration with partner factories.

Water usage initiatives

Besides reducing water usage in production activities, ITO EN also monitors water usage and wastewater of contract manufacturers and seeks to minimize the impact of production activities on the environment.

NS System developed in collaboration with Toyo Seikan Co., Ltd.

Manufacturing method which does not involve the use of sterilizing agents to sterilize bottles and therefore helps reduce water usage and lessen the impact of wastewater on the environment (as there is no need for water to remove sterilants).

* NS System: Non-Sterilant (i.e., not using any sterilizer)Initiatives to reduce water usage at Okinawa Factory

At our Okinawa Factory, we are actively working to save water by reusing the water used for cooling and washing in other appropriate applications.

Measures to address natural disaster and water risks

In its beverage business, ITO EN adopts a "fabless" business model (except in Okinawa), owning no factories of its own and outsourcing production to contract manufacturers across Japan. This allows us to adapt flexibly even when natural disaster, drought or interruption of the water supply makes production difficult in a certain region.

We also regularly check whether our bases as well as our suppliers and other partners in our supply chain are located in water stressed regions or flood-prone areas, and we take measures to address such risks.

Water risk assessments

In addition to monitoring and managing water usage at each base, ITO EN also strives to reduce water usage in its production activities by setting reduction targets.

Every year since FY2019, we have assessed and identified water risk by carrying out a comprehensive risk assessment of water stress for our production bases, suppliers of important raw materials and contract factories using the WRI (World Resources Institute) Aqueduct tools.* The geographic areas that are indicated as having “high” or greater water stress and water resource depletion are defined as highly water-stressed areas. As a result of an analysis, we have confirmed that none of our company-owned factories or major contract factories are located in highly water-stressed areas. Going forward, we will continue to monitor water stress, assess and identify water risk according to changes in the business environment and other phenomena, and take measures to reduce water usage where necessary.

We are also involved in water source conservation activities in collaboration with suppliers which mainly use groundwater in their business activities.

Water source conservation activities

In collaboration with partner factories, we also participate in conservation activities protecting the water sources near our production bases.

Every year since 2022, ITO EN employees participated in the Forest Development with Corporate Participation project promoted by Gunma Prefecture together with Nihon Canpack Co., Ltd.—a beverage product manufacturing contractor. Our employees are taking part in forest conservation activities which will help protect water resource areas surrounding the Akagi factory of Nihon Canpack Co., Ltd., including forest thinning to maintain and develop a healthy forest and improve the environment, improving the river environment and vegetation, weeding to restore and maintain ecosystems, and removing sludge.

Such forest development activities can be expected to be beneficial for the environment in various ways, including recovering some of the essential forest functions, for example, mitigation of flood damage, restoration of water sources and protection from natural disasters.

In June 2024, we also expanded our collaborations by conducting additional watershed conservation activities in partnership with Gold-Pak Co., Ltd., another beverage manufacturing partner, working jointly with local municipal governments.

Sustainable containers and packaging

The ITO EN Group is actively working on a range of initiatives including developing technologies which will help reduce the weight of PET bottles and plastic usage, and introducing environmentally friendly paper packaging. We will contribute to the realization of a sustainable society by increasing our focus on the 3Rs (Recycle, Reduce, Replace & Reuse) + Clean (environmental conservation) based on the ITO EN Group Policy on Plastics and the ITO EN Group Policy on Containers and Packaging, aiming to realize a recycling-oriented society.

Initiatives for 3R

Recycling (circulation of resources)

100% recyclable PET bottles

To ensure that collected PET bottles are utilized more effectively as resources, we are involved in the Bottle-to-Bottle initiative, aiming to increase the ratio of recycled materials (including bio-derived materials) used as materials for producing PET bottles to 100% by 2030. We switched our Oi Ocha 600 mL bottles to fully recyclable PET bottles and, in an industry first, we launched Oi Ocha microwaveable 345 mL PET plastic bottles using 100% recycled plastic in 2019. We have also worked to reduce the use of newly produced petroleum-derived resources in production, including launching unlabeled Oi Ocha Green Tea in 2021.

To realize a more recycling-oriented society, we are promoting the Bottle-to-Bottle initiative in collaboration with local governments and business partners.

Initiatives using empty container collection boxes installed next to vending machines

In FY2021, we launched the Bottle-to-Bottle initiative at the ITO EN head office building in Shibuya-ku, Tokyo. Through our route sales activities, we have also started a Bottle-to-Bottle initiative for recycling some of the used PET bottles collected from empty container collection boxes installed next to vending machines.

Aluminum-free eco-containers

Aluminum-free eco-containers are paper containers which can extend product shelf life at room temperature and which use a barrier type eco-friendly film instead of aluminum. Since aluminum packaging requires a special process to separate the paper from the aluminum, it is generally not recycled and disposed of together with combustible waste; however, aluminum-free eco-containers do not use aluminum foil and can therefore be recycled like milk cartons.

Reduce (resource-saving)

Reduction of weight of containers and packaging

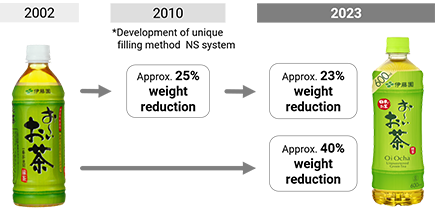

We are working to further reduce the weight of containers and packaging, including plastic bottles, bottle caps, and labels, and reduce the amounts of materials used. We are increasing the production of bottles without labels. We aim to contribute to the creation of a sustainable society and environment. We use NS System,* an environmentally friendly filling method developed in collaboration with Toyo Seikan Co., Ltd., primarily for Oi Ocha, the Company's mainstay product. The NS System not only eliminates the need for large amounts of water to remove sterilants because sterilizing agents are not used to sterilize bottles, it also minimizes the time bottles are exposed to high temperatures, allowing us to produce lighter weight bottles because a lower level of heat resistance is required.

Changes in the reduction of the weight of products contained in plastic bottles

After the renewal of the Oi Ocha packaging in 2002 and with the introduction of the NS System—a unique filling method—developed in 2010, through the use of environmentally-conscious PET plastic bottles we have reduced the amount of plastic used in bottles, caps and labels by around 40% per bottle (Oi Ocha 500-600 ml PET plastic bottles).

Reducing plastic used in vending machines

By switching from conventional three-dimensional molded display samples to flat card-type displays, we reduced plastic usage in FY2023 by 27.2% compared with FY2018 and improved operational efficiency. In addition, materials from disused molded displays are upcycled for internal use, helping to build a resource-circulation system.

Replace & Reuse(replacing with environmentally friendly materials and reusable containers)

Switching to plant-based biodegradable materials

We are using Green Planet™*1 in our biodegradable telescopic*2 straws(ECO straws) used for Oi Ocha in paper containers and other products.

We use plant-derived biodegradable filters for tea bags for Oi Ocha Green Tea and other major items. We are also replacing the individual plastic packaging of tea bags with paper packaging.

Biodiversity conservation

The ITO EN Group conducts its business activities by taking advantage of the rich blessings of nature, from raw material procurement to disposal. We recognize that the preservation of biodiversity is the foundation of the rich blessings of nature and the foundation of our business activities.

Since July 2023, the Group has joined the 30by30* Alliance for Biodiversity, an initiative led by the Ministry of the Environment.

*The 30by30 (thirty by thirty) target is to effectively conserve at least 30% of the land and ocean as vital eco-systems by 2030 with a view toward halting and reversing the lose of biodiversity (being nature positive) by 2030.

Since April 2024, we have expressed our alignment with the recommendations of the Taskforce on Nature-related Financial Disclosures (TNFD) and have taken part in the TNFD Forum.*

*The TNFD Forum is a group of stakeholders who support the TNFD’s discussions, The group is composed of companies, institutions and organizations aligned with the philosophy of the TNFD.

To ensure that we can continue to enjoy the bounty of nature in the future, we will promote initiatives for the conservation and restoration of biodiversity through our business activities based on ITO EN Group Policy on Biodiversity Conservation.

In the Tea-Producing Region Development Project, we are promoting recycling-oriented agriculture by developing technologies for reduced pesticide use and organic cultivation, as well as composting tea husks in anticipation of further demand growth in overseas markets.

Promoting waste reduction / resource recycling

For the realization of a sustainable society, ITO EN reduces waste and promotes the effective use of resources and the upcycling of used tea leaves into various products.

Used Tea Leaves Recycling System

ITO EN recycles tea leaves generated from the production of Oi Ocha and other tea beverages as fertilizer and animal feed. Further, ITO EN has developed a unique Used Tea Leaves Recycling System, since 2000, under which we use a portion of the used tea leaves as a component in various products, including paper products, building materials and resins, which are manufactured into a variety of products and distributed by our partner companies. Through these efforts, we are saving resources by reducing the amount of raw materials used and developing new products that take advantage of the tea's characteristics such as its aroma, deodorizing and antibacterial effects.In addition, used tea leaves are blended with materials such as paper without dehydrating them. This means that they do not go through a drying process, which would involve the consumption of oil resources and CO2 emissions. This initiative has three environmental benefits: resource conservation, reduction of CO2 emissions, and recycling.

Initiatives to reduce food waste

Aiming to reduce food waste, we have incorporated the reduction of beverage waste and waste tea leaves generated across the Group into our environmental management system (ISO14001) to promote reductions. We will continue making efficient improvements and implementing initiatives to maintain and improve our food waste recycling rate.

Aiming to solve environmental issues (prevention of global warming, reduction of waste, etc.) at every stage of the supply chain, from production to distribution and sales, we are working on transitioning to labels stating “best before month” instead of a specific date.

We launched this initiative in April 2013 and, as a result of wider implementation in January 2018, now around 80% of all product items (beverages and tea leaf products) have labels stating "best before month." The shift to labels stating "best before month" can be expected to reduce food loss and increase distribution efficiency, thereby reducing our CO2 emissions and reducing the environmental impact of our business activities.

Compliance with environmental laws and regulations

Every year, all our business sites verify compliance with laws and regulations based on a register of environmental laws and regulations and our Legal Department, Internal Auditing Department and the ISO Secretariat also carry out audits and onsite inspections. We have incurred no environmental related penalties or punitive costs in the past three years.

Moreover, for waste-related operations, we have introduced an electronic manifest management system to sales bases to promote strict compliance with laws and regulations and improvement in work efficiency.

Going forward, the ITO EN Group will continue contributing to the realization of a sustainable society and environment by ensuring compliance with laws and regulations and by supporting government policies to solve environmental issues such as climate change.