Japanese Green Tea

Production Process

There are a variety of operations and processes involved in manufacturing Japanese green tea, from tea field cultivation to tea factory processing, and our highly-skilled team of experts are dedicated to the art of growing and making tea.

Tea fields to Crude tea (Aracha)

At factories in the areas where tea is grown, freshly picked raw tea leaves are processed into the semi-finished product of crude tea. Crude tea is not usually sold to end users since the leaves are of non-uniform size and shape, and they contain too much moisture and have a "grassy" aroma.

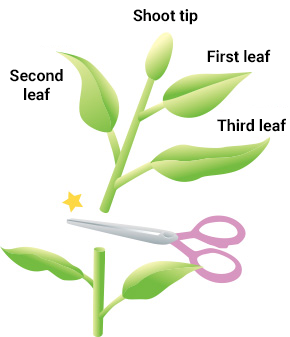

1. Picking

When picking Sencha tea by hand, usually stems with a shoot and two or three opened leaves are picked. When picking by machine, usually the picked stems have a shoot and four or five opened leaves. The freshly picked raw tea leaves are still alive and breathing, and give off heat.

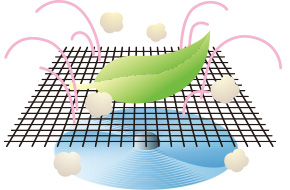

2. Fanning and humidifying

If the freshly picked leaves are left as they are, they immediately begin to ferment and heat up. To prevent loss of quality and maintain freshness, the raw leaves are fanned with damp air to help maintain their moisture and dissipate the heat given off by the fresh leaves.

3. Steaming

To halt the oxidizing and fermentation action of enzymes on the leaves, preserve their green color and remove the "grassy" odor, the tea leaves are steamed using non-pressurized steam. The length of the steaming process is said to be a key determinant in the tea's flavor, aroma and color.

The steaming process has a significant effect on the Sencha's color and quality. The longer the steaming time, the more easily the tea leaves' cellular membrane breaks down during later processing. This in turn leads to cloudiness in the tea's color. However, longer-steamed leaves have a brighter luster while astringency and fragrance is reduced.

Steaming Time and

Tea Characteristics

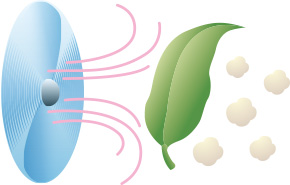

4. Cooling

If the steamed tea leaves are left at high temperature, they will lose their bright color and their flavor and aroma will be spoiled. For these reasons, to preserve the tea's luster and color as well as flavor and aroma, air is blown over the steamed leaves to rapidly cool them to normal room temperature.

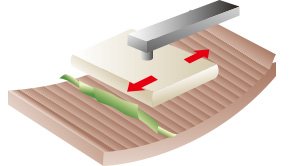

5. Pressing

To enhance luster, color, flavor and aroma, and shorten the first rolling stage, the leaves are pressed while being exposed to dry, hot air from a fan to remove moisture. (This process removes steam dew from the leaves' surface and increases the drying effect.)

6. First rolling

To soften the leaves and lower the internal moisture content, hot, dry air is blown over the leaves while applying pressure and appropriate friction and compression.

7. Rolling and twisting

The leaves are pressed in a bundle without applying heat to break up their structure and make it easier for the components of the tea leaves to be released when it is made into tea. This process also compensates for any lack of pressing during the first rolling process and moisture content is made uniform.

8. Second rolling

Since the tea leaves wither after rolling and twisting and are still relatively high in moisture and uneven in size and shape, they are rolled while having hot, dry air blown on them. They are then dried and disentangled ready for final rolling.

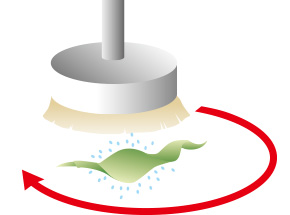

9. Final rolling

To give the tea leaves their characteristic needle shape, they are rolled in one direction only, similar to the action of manual rolling, while further reducing moisture content.

10. Drying

The leaves have a moisture content of approximately 10-13% after final rolling, and this is reduced to 5% with hot-air drying. This allows long-term storage and further draws out their distinctive aroma.

Crude tea to

Final products

Crude tea is uneven in shape and its moisture content is still high, meaning it can easily deteriorate. For these reasons, crude tea does not yet have the value of a finished product. Consequently, it requires secondary processing before it can be sold as a finished product. This enables it to be stored and allows the final product to be adapted to local consumer tastes. Its value as a final product is increased by both appearance and content. This process is so important that each company within the tea manufacturing industry keeps it a secret.

Secondary processing involves drying, sorting, cutting and shaping, and grading using blown air and electrical sensitivity. Blending is carried out according to tastes in the consuming region and price. Specific methods and procedures are extremely complex and vary depending on the factory at which they are performed. Broadly speaking, there are two main approaches. Under the pre-roasting method, the crude tea is roasted, sorted, and shaped, while under the post-roasting method, the crude tea is first shaped and sorted according to shape and weight and is then roasted to the optimum level for each size.